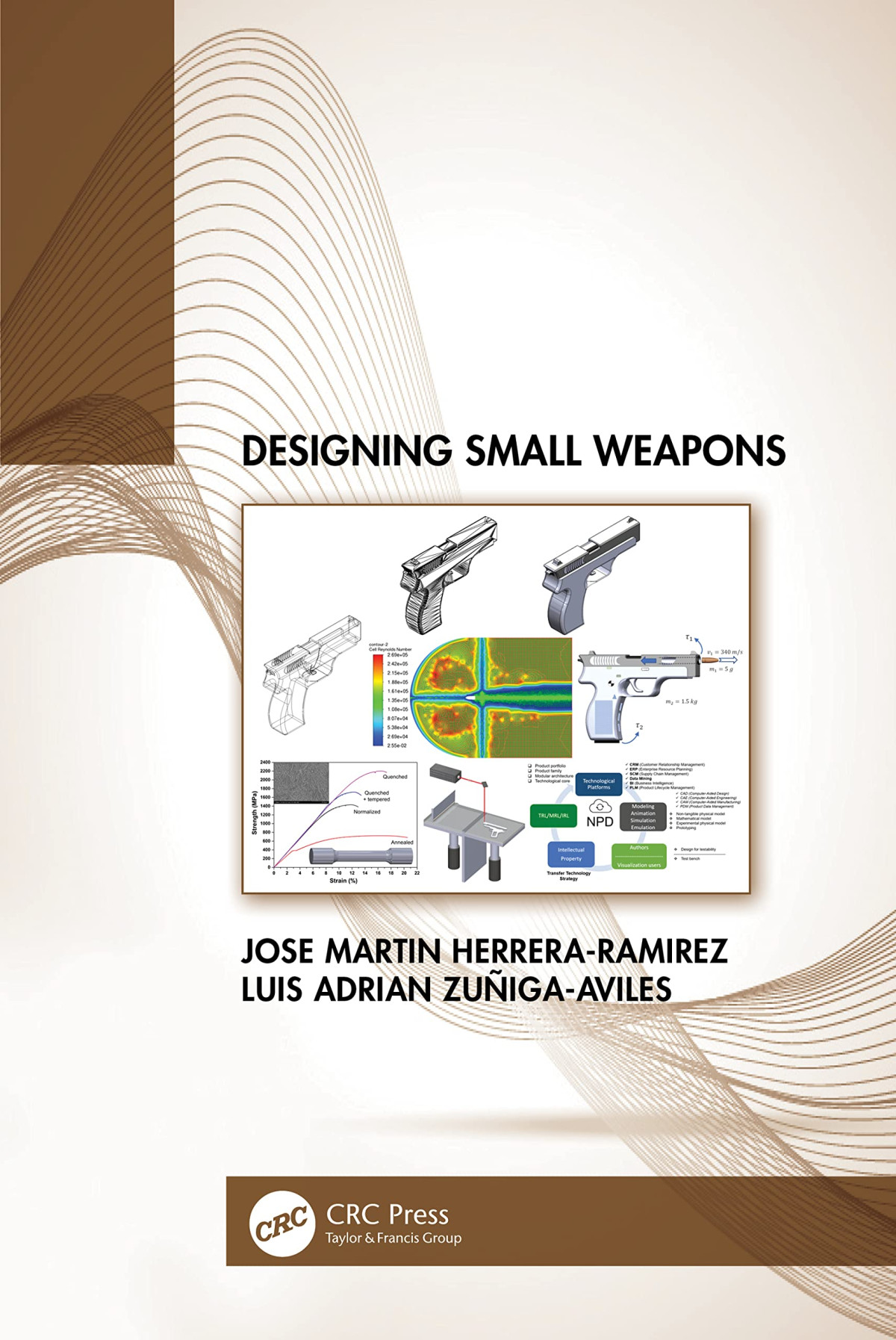

Designing Small Weapons 1st Edition by Jose Martin Herrera Ramirez, Luis Adrian Zuñiga Aviles ISBN 9781003196808 1003196802

$50.00 Original price was: $50.00.$25.00Current price is: $25.00.

Designing Small Weapons 1st Edition by Jose Martin Herrera Ramirez, Luis Adrian Zuñiga Aviles – Ebook PDF Instant Download/Delivery: 9781003196808 ,1003196802

Full download Designing Small Weapons 1st Edition after payment

Product details:

ISBN 10: 1003196802

ISBN 13: 9781003196808

Author: Jose Martin Herrera Ramirez, Luis Adrian Zuñiga Aviles

Designing Small Weapons 1st Edition Table of contents:

Chapter 1 History of the Design of Small Weapons

1.1 Introduction

1.1.1 The First Period

1.1.2 The Second Period

1.1.3 The Third Period

1.1.4 The Fourth Period

1.2 Evolution of Firearms

1.2.1 The Hand Cannon

1.2.2 The Matchlock System

1.2.3 The Wheellock System

1.2.4 The Snaphaunce System

1.2.5 The Flintlock System

1.2.6 The Percussion System

1.2.7 The Dreyse Needle System

1.2.8 The Pinfire System

1.2.9 The Rimfire Ammunition

1.2.10 The Centerfire Ammunition

1.2.11 The Rifling System

1.2.12 The Revolver

1.2.13 Self-Loading Firearms

1.3 Classification of Firearms

1.3.1 Classification by the Level of Harm

1.3.1.1 Lethal Firearms

1.3.1.2 Non-lethal Firearms

1.3.2 Classification by the Traditional Structure

1.3.2.1 Firearms

1.3.2.2 Conventional Weapons

1.3.2.3 Non-conventional Weapons

1.3.3 Classification by the Portability

1.3.3.1 Small Arms

1.3.3.2 Light Weapons

1.3.3.3 Heavy Weapons

1.3.4 Classification by the Physical Characteristics, Size, and Support

1.3.4.1 Short

1.3.4.2 Long

1.3.5 Classification by the Weapon Action

1.3.5.1 Single-Shot Action

1.3.5.2 Repeating Action

1.3.5.3 Semi-automatic Action

1.3.5.4 Burst Action

1.3.5.5 (Fully) Automatic Action

1.3.6 Classification by the Type of Firearm

1.3.6.1 Revolver

1.3.6.2 Pistol

1.3.6.3 Shotgun

1.3.6.4 Rifle or Carbine

1.3.6.5 Assault Rifle

1.3.6.6 Sub-machine Gun

1.3.6.7 Machine Gun

1.3.6.8 Other Type of Firearms

1.4 Evolution of Weapon Materials

1.4.1 Stone, Wood, and Bone

1.4.2 Metals

1.4.2.1 Bronze

1.4.2.2 Iron

1.4.2.3 Steel

1.4.2.4 Aluminum

1.4.3 Polymers

1.4.4 Composites

1.4.5 Ceramics

1.5 Evolution of Firearm Manufacturing Processes

1.6 Evolution of Design Tools

1.6.1 The First Period

1.6.2 The Second Period

1.6.3 The Third Period

References

Chapter 2 Beginning the Product Design

2.1 Introduction

2.2 Product Lifecycle Management

2.3 Design Methodologies

2.3.1 Expectation for Innovation Using the Market Pull

2.3.2 Expectation for Innovation Using the Technology Push

2.3.3 Design Criteria

2.3.4 Design Attributes

2.3.5 Requirements

2.3.6 Functional Requirements

2.3.7 Design Parameters

2.3.8 Constraints

2.3.9 Commonality Index

2.3.10 DFA Index

2.3.11 Modeling and Simulation

2.3.12 PDMs Frameworks

2.4 A Case Study Based on PDMs Toolkit

2.4.1 Preliminary Topics

2.4.2 Market Pull Analysis

2.4.3 Design Criteria

2.4.4 Requirements

2.4.5 Functional Requirements

2.4.6 Design Parameters

2.4.7 Constraints

2.4.8 Commonality Index

2.4.9 DFA Index

2.4.10 Product Portfolio

2.5 Closing Remarks and Perspectives

References

Chapter 3 Custom and Functional Requirements

3.1 Introduction

3.2 Requirements

3.3 Requirements to Reach Readiness of a System

3.4 Requirement Identification

3.5 Determination of FR and Assessment of Its Difficulty

3.6 Determination of DPs Using Axiomatic Design

3.7 Relationship DP to FR

3.8 Relationship Critical Design Parameter (CDP) to Test Bench Feature (TBF)

3.9 Relationship Process Variable (PV) to DP

3.10 Determination of Instruments to Technology Transfer

3.11 Closing Remarks and Perspectives

References

Chapter 4 CAD Modeling and CAE Simulation

4.1 Introduction

4.2 Modeling and Simulation

4.3 CAD Modeling

4.3.1 Digital Model Obtaining

4.3.2 Materials Database Storage

4.3.3 Bill of Material Property Manager

4.3.4 CAD Animation

4.3.5 Interference Detection

4.3.6 Tolerance Stack-up Analysis

4.3.7 CAD Drawings

4.4 CAE Simulation

4.4.1 CAD Model Treatment

4.4.2 CAE Analysis by FEA

4.4.3 CAE Motion

4.4.4 Flow CFD

4.4.5 CAE Multibody Dynamics

4.4.6 CAE Co-Simulation

4.4.7 CAE Multi-Domain

4.4.8 CAE Bullet Penetration and Perforation by Explicit Dynamics

4.4.9 Thermal Simulation by FEA, CFD, and FSI

4.4.10 CAE Emulation

4.5 CAD-CAE Documentation and Report

4.6 Closing Remarks and Perspectives

References

Chapter 5 CAM Assessment and Rapid Prototyping

5.1 Introduction

5.2 Technical Preliminaries

5.3 CAM Assessment

5.4 CNC Machining

5.5 Laser Cutting

5.6 3D Printing

5.7 Prototyping Workshop

5.8 Rapid Prototyping

5.9 Rapid Tooling and Manufacturing Devices

5.10 Industry 4.0

5.11 Closing Remarks and Perspectives

References

Chapter 6 Experimental Physical Models, Test Benches, and Prototypes

6.1 Introduction

6.2 Tests Protocols and Product Validation Process

6.3 Firearm Usability and UX

6.4 Firearm EPMs and Demonstration Prototypes

6.5 Test Benches and Standards to Firearm Performance

6.6 Firearm Prototypes in Real Environment

6.7 Polymer Firearms and 3D Printed Prototypes

6.8 Firearm Performance Case Studies

6.9 Closing Remarks and Perspectives

References

Chapter 7 Materials Used in the Production of Small Weapons

7.1 Introduction

7.2 Classification of Materials

7.2.1 Metals

7.2.2 Polymers

7.2.3 Ceramics

7.2.4 Composites

7.3 Binary Phase Diagrams

7.4 The Fe-C Phase Diagram

7.5 Aluminum Alloys Phase Diagrams

7.6 Mechanical Properties of Materials

7.7 Steels

7.7.1 Classification of Steels

7.7.2 Influence of Alloying and Residual Elements on Steel Properties

7.7.3 Designation of Steels

7.8 Aluminum Alloys

7.8.1 Classification of Aluminum Alloys

7.8.2 Designation of Wrought Aluminum Alloys

7.8.3 Influence of Alloying Elements and Impurities on Aluminum Alloy Properties

7.9 Titanium Alloys

7.10 Synthetic Polymers

7.10.1 Glass Transition Temperature

7.10.2 Nomenclature of Synthetic Polymers

7.10.3 Classification of Polymers by Properties

7.11 Composites

7.11.1 Matrices

7.11.2 Reinforcements

7.12 Ceramics

7.13 Closing Remarks

References

Chapter 8 Heat Treatments and Surface Hardening of Small Weapon Components

8.1 Introduction

8.2 Heat Treatments of Steels

8.2.1 The TTT Diagram

8.2.2 Annealing

8.2.2.1 Full Annealing

8.2.2.2 Process Annealing

8.2.2.3 Spheroidizing Annealing

8.2.3 Normalizing

8.2.4 Hardening

8.2.5 Tempering

8.2.6 Martempering

8.2.7 Austempering

8.3 Surface Hardening of Steels

8.3.1 Carburizing

8.3.2 Nitriding

8.3.3 Carbonitriding

8.3.4 Induction Hardening

8.3.5 Flame Hardening

8.4 Heat Treatments of Aluminum Alloys

8.5 Anodizing of Aluminum Alloys

8.6 A Case Study Based on Heat Treatments of Steels

8.7 Closing Remarks

References

Chapter 9 Manufacturing Processes for Small Weapon Components

9.1 Introduction

9.2 Casting

9.3 Forming

9.3.1 Forging

9.3.2 Extrusion

9.3.3 Stamping

9.4 Polymer Processes

9.5 Powder Metallurgy

9.6 Material Removal Processes

9.7 Additive Manufacturing Processes

9.8 Finishing, Assembly, and Testing

9.8.1 Finishing

9.8.2 Assembly

9.8.3 Testing

9.9 Closing Remarks

References

Index

People also search for Designing Small Weapons 1st Edition:

small compound design ideas

how to draw a small zebra

small design ideas

designing weapons for the military

designing weapons

Tags: Jose Martin Herrera Ramirez, Luis Adrian Zuñiga Aviles, Designing Small Weapons

You may also like…

Romance - Other Romance Categories

American Fairytale Dreamers 1st Edition by Adriana Herrera 1488054061 9781488054068

Erotica - Fiction

Technique - Military equipment: Weapon

British Coastal Weapons vs German Coastal Weapons The Dover Strait 1940 44 1st Edition Neil Short

Uncategorized

The Ethics of Virtual and Augmented Reality Building Worlds 1st Edition Erick Jose Ramirez

Technique - Military equipment: Weapon

Business & Economics - Sales & Marketing

Romance - Other Romance Categories