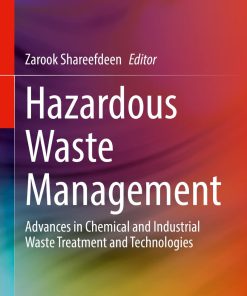

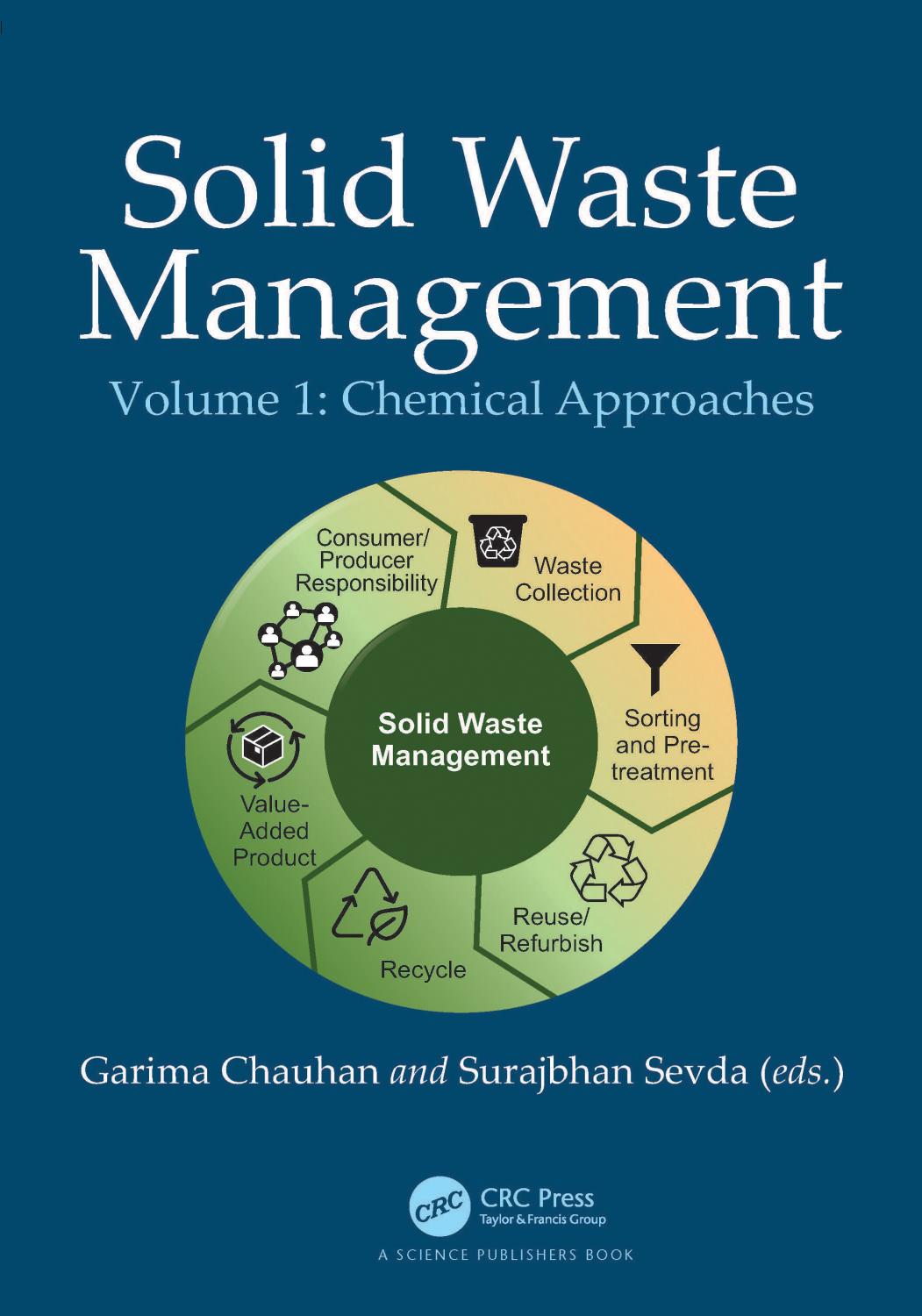

Solid Waste Management Chemical Approaches Volume 1 1st Edition by Garima Chauhan, Surajbhan Sevda ISBN 9781032039008 1032039000

$50.00 Original price was: $50.00.$25.00Current price is: $25.00.

Solid Waste Management Chemical Approaches Volume 1 1st Edition by Garima Chauhan, Surajbhan Sevda – Ebook PDF Instant Download/Delivery: 9781032039008 ,1032039000

Full download Solid Waste Management Chemical Approaches Volume 1 1st Edition after payment

Product details:

ISBN 10: 1032039000

ISBN 13: 9781032039008

Author: Garima Chauhan, Surajbhan Sevda

Solid Waste Management Chemical Approaches Volume 1 1st Edition Table of contents:

1. Waste: Impact, Trends, Interventions, and Future Goals

1 Introduction

1.1 Food or organic materials

1.2 Electronic waste

1.3 Clothing waste

1.4 Packaging waste

1.5 Chemical waste

2 Possible Consequences

2.1 Climate and environmental damage

2.2 Resource depletion

2.3 Public health

2.4 Ecological and wildlife disruption

3 Waste Prevention And Management

3.1 Reduce

3.2 Repair

3.3 Repurpose

3.4 Redistribute

3.5 Recycle

3.6 Responsible discarding

4 Redefining Waste

4.1 Awareness and education related challenges

4.2 Motivational challenges

4.3 Behavioral nudges

References

2. Insights Into Covid-19 Waste Management: Sources, Composition, Disposal and Challenges

1 Introduction

2 Sources Of Covid-19 Waste and Their Composition

2.1 Medical gloves: Sources and composition

2.2 Face masks: Sources and composition

2.3 Protective clothing sources and composition

2.4 Goggles and face shields: Sources and composition

2.5 COVID-19 test kits

2.6 Sanitizer and disinfectant bottles: Sources and composition

2.7 Plastic sheets and packaging material: Sources and composition

3 Classification Of Covid-19 Waste And Disposal Practices

4 Disposal Practices

4.1 Waste collection and pre-treatment

4.2 Waste segregation and storage

4.3 Waste collection and transportation

4.4 Disposal of COVID-19 waste

5 Challenges And Regulations

5.1 Regulations for handling COVID-19 solid waste

6 Summary

Acknowledgement

References

3. Towards Efficient Methods in E-Waste Disassembling: The Circular Economy Approach

1 Introduction

2 Framework Of Disassembling Waste Electrical and Electronic Equipment

3 Methods Of E-Waste Disassembly

3.1 Manual disassembly

3.2 Mechanical processing in disassembly of e-waste

4 Processing Machines Used In E-Waste Disassembly Plants

4.1 Hammer mills

4.2 Shredders

4.3 Crushers

5 Materials and Fraction Separation after Preliminary Processing of E-Waste

5.1 Magnetic separation

5.2 Eddy current separation

5.3 Gravity separators

5.4 Electrostatic separation

5.5 Cyclone separation

5.6 X-ray and optical separators

6 Characteristics Of Disassembling For Selected Categories Of E-Waste Equipment

6.1 Disassembly of cooling appliances

6.2 Disassembly of information technology equipment

6.3 Disassembly of small home appliances

7 Discussion and Conclusions

References

4. Insights Into Metallurgical Processes For Sustainable Recovery Of Metals From Electronic Waste

1 Introduction

2 Pyrometallurgical Process

2.1 Industrial processes

2.2 Laboratory scale processes

2.3 Limitations of pyrometallurgical processes

3 Hydrometallurgical Processes

3.1 Mineral acid leaching

3.2 Cyanide leaching

3.3 Thiosulfate leaching

3.4 Thiourea leaching

3.5 Halide leaching

3.6 Chelation technology

3.7 Ammonia-ammonia salt leaching

3.8 Limitations of hydrometallurgical processes

4 Conclusion

References

5. Energy Recovery from Electronic Waste: A Critical Assessment

1 Introduction

2 E-Waste Polymers

2.1 E-waste polymers

2.2 Thermal degradation behaviour

2.3 Organic bi-products and gaseous emissions

3 Thermal Treatment Of E-Waste

3.1 Pyrolysis and combustion

3.2 Open burning

4 Pollutant Emissions

4.1 Emissions of fine particulates

4.2 Dioxin and furan generation

5 Energy Savings Through Material Recovery

6 Prospects Of Energy Recovery From E-Waste

Acknowledgements

References

6. Eco-Design Strategies for Recycling of E-Waste

1 Introduction

2 E-Waste Classification

3 Conventional Approach for E-Waste Recycling and Their Shortfalls

3.1 Pyrometallurgical process of metal recovery

3.2 Hydrometallurgical process of e-waste recycling

3.3 Biometallurgical process of e-waste recycling

3.4 Recycling of plastics from e-waste

4 Major E-Waste Recycling Plants in India and Worldwide

5 Need for Eco-Design Strategies

6 Different Aspects of Eco-Design

6.1 Environmental aspect

6.2 Technological aspect

6.3 Economic aspect

6.4 Social aspect

7 Summary and Future Outlook

Acknowledgment

References

7. Recovery and Conversion of E-Waste Plastic via Physical and Chemical Routes

1 Introduction

2 Physical Separation

2.1 Gravity separation

2.2 Magnetic separation

2.3 Electrostatic separation

2.4 Flotation

2.5 Perspective of physical separation processes

3 Chemical Recycling

3.1 Pyrolysis

3.2 Catalytic pyrolysis

3.3 Gasification

3.4 Supercritical fluid (SCF) technology

Conclusions

Acknowledgment

References

8. Chemical Recycling of Plastic Waste

1 Introduction

2 Plastic Recycling

2.1 Primary recycling

2.2 Secondary recycling

2.3 Tertiary recycling

2.4 Quaternary recycling

3 Chemical Recycling of Plastics

3.1 Chemolysis

3.2 Pyrolysis

4 Recycling of Plastic Wastes Under Mild Conditions

5 Summary and Conclusion

References

9. Degradation Mechanism and Valorization of Waste Plastic to Energy and Chemicals

1 Introduction

2 Chemistry Of Plastic Material

3 Environmental, Social and Economic Effects of Plastic Pollution

3 Mechanism of Plastic Degradation

5 Factors Affecting Plastic Degradation

5.1 Type of polymer

5.2 Types of additives

5.3 Environment

6 Thermal Treatment Techniques

7 Present Status and Future Trends

8 Conclusion and Future Direction

References

10. Catalytic Pyrolysis of Waste Plastics for the Production of Liquid Fuels

1 Introduction

2 Waste Plastic Categories

2.1 Polyethylene terephthalate (PET)

2.2 High-density polyethylene (HDPE)

2.3 Low-density polyethylene (LDPE)

2.4 Polyvinyl chloride (PVC)

2.5 Polypropylene (PP) and polyethylene (PE)

2.6 Polystyrene (PS)

3 Types of Pyrolysis Catalyst

4 Mechanism of Catalytic Pyrolysis

5 Pyrolysis Reactor Technologies

5.1 Batch and semi-batch reactors

5.2 Fixed bed catalytic reactors (FBCRs)

5.3 Fluidized bed reactors (FBRs)

5.4 Conical spouted bed reactors (CSBRs)

5.5 Vacuum reactors

5.6 Screw kiln reactors (SKR)

5.7 Microwave-assisted reactors (MAR)

5.8 Plasma-assisted reactors (PARs)

6 Influence of Operating Conditions

6.1 Temperature

6.2 Heating rate

6.3 Residence time

6.4 Plastic to catalyst ratio

7 Industrial-Scale Catalytic Pyrolysis Plants

8 Conclusions

References

11. Agro-Residue Waste Management Sources, Recent Practices, and Applications

1 Introduction

2 Sources of Solid Waste

2.1 Electronic waste

2.2 Agricultural waste

2.3 Plastic waste

2.4 Other wastes

3 Impact of Solid Waste on Health and Environment

3.1 Effect of solid waste disposal on human health

3.2 Effect of solid waste disposal on the environment

4 Ways Adopted to Utilize Waste for Synthesizing Valueadded Products

4.1 Incineration

4.2 Gasification

4.3 Composting

4.4 Pyrolysis

4.5 Hydrothermal carbonization

4.6 Bioconversion

5 Application of Products for Various Engineering Processes

5.1 Synthesizing adsorbents

5.2 Synthesizing coagulants

6 Experimental Studies for Synthesizing Useful Products From Bio-Waste

6.1 Carbonization of bio-waste from different methods

6.2 Characterization of developed product

6.3 Application of developed product into various areas of water treatment

7 Conclusions

References

12. Production of Biofuels from Waste Biomass Via Fischer-Tropsch Synthesis an Overview

1 Introduction

2 Feedstock And Pretreatment

2.1 Waste biomass for syngas production

2.2 Pretreatment of waste biomass for syngas production

2.3 Physical processes

2.4 Thermochemical processes

3 Syngas Production

3.1 Gasification

3.2 Reforming

4 Syngas Cleaning and Conditioning

4.1 Syngas cleaning

4.2 Adjustment of H2/CO ratio

5 Fischer-Tropsch Synthesis

5.1 Fischer-tropsch product composition and distribution

5.2 Fischer-tropsch reactor types

6 Refining of Fischer-Tropsch Syncrude

6.1 Property requirements for synthetic fuel products

6.2 Refining of fischer-tropsch products

Refinery technology selection

7 Technical, Economical, and Environmental Perspectives of Liquid Fuel Production Via Fischertropsch Synthesis

References

13. Waste to Fuels Via The Fischer-Tropsch Process a Modularized Approach

1 Introduction

1.1 Technology options for waste-to-energy

1.2 Fischer-tropsch process

2 Commercialization of Fischer-Tropsch Biofuels

2.1 Early projects (2008–2015)

2.2 Recent developments (2015 – present)

3 Economic Barriers For Fischer-Tropsch Biofuels

3.1 Oil price dependency

3.2 Capital cost

3.3 Cost of raw material and transportation

3.4 Scale

4 A Case for Modularization

5 Design Strategies for Modular Fischer-Tropsch Biofuels

5.1 Typical Fischer-Tropsch BTL and WTL plants

5.2 Syngas generation from biomass and waste

5.3 Removing air separation unit and recycle

5.4 Fischer-tropsch synthesis at high conversion

5.5 Refining vs upgrading

5.6 Co-generation electricity and fuels

6 Concluding Remarks

Acknowledgements

List of Abbreviations

References

14. Waste to Carbon: A Sustainable Approach for Converting Agricultural Wastes into Bio-Based Carbon Adsorbents for Wastewater Treatment

1 Introduction

2 Conversion of Aws to AC

2.1 Pre-treatment

2.2 Carbonization

2.3 Activation

3 Conversion Parameters

4 Aw-Derived Ac Adsorbents In Water Treatment Applications

4.1 Removal of conventional contaminants

4.2 Removal of emerging contaminants

5 Conclusions

6 Challenges and Future Directions

List Of Abbreviations

References

15. Energy Recovery from Municipal Wastewater Sludge

1 Introduction

2 Overview of Sludge Production

3 MWS Characteristic

3.1 Physical characteristics

3.2 Chemical characteristics

3.3 Comparison of sludge to coal and biomass as a source of fuel

4 Sludge Management and Treatment

4.1 Current handling and environmental impact

4.2 Sludge treatment and solution

5 Energy Recovery from Municipal Wastewater Sludge

5.1 Chemical conversion

5.2 Thermochemical conversion

5.3 Biochemical conversion

5.4 Bioelectrochemical conversion

6 Economic Analysis

7 Conclusions

Acknowledgements

References

Index

People also search for Solid Waste Management Chemical Approaches Volume 1 1st Edition:

solid waste characterization study

solid waste disposal methods apes

a solid waste can be a

a solid waste

a method of solid waste disposal

Tags: Garima Chauhan, Surajbhan Sevda, Solid Waste Management, Chemical Approaches

You may also like…

Uncategorized

Solid Waste Policies and Strategies Issues Challenges and Case Studies Sadhan Kumar Ghosh (Editor)

Engineering - Environmental

Chemistry - Technical & Industrial Chemistry

Uncategorized

Engineering - Environmental

Handbook of Solid Waste Management 1st Edition by Chinnappan Baskar 981164229X 9789811642296

Politics & Philosophy - Anthropology

The Struggle for Development and Democracy Volume 1 New Approaches 1st Edition Alessandro Olsaretti

Biology and other natural sciences - Biotechnology